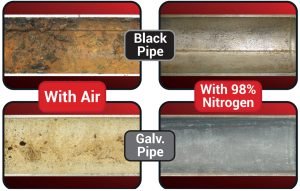

Dry or pre-action (a two-step activation) fire sprinkler systems are typically filled with compressed air supplied by an air compressor, which maintains pressure throughout the system until one or more activation points occur. Upon activation water flows throughout the system to the activation point(s) and is expelled through the fire sprinkler heads. Internal corrosion is a growing and costly problem for these systems. The presence of oxygen in the compressed air along with any residual water remaining from required testing and condensations leads to corrosion, pinhole leaks, obstructions and costly repairs. (See: What causes pinhole leaks in fire sprinkler systems?)

What can I do to prevent corrosion in my dry fire sprinkler system?

The answer is to introduce and maintain 98% pure nitrogen in the system to effectively arrest corrosion. It’s important to remember that a properly maintained nitrogen system will not reverse corrosion, rather it stops corrosion from getting worse, and prevents it in a new system or any new piping.

Our partners at South-Tek Systems manufacture the most efficient and cost effective engineered corrosion systems on the market. Their dual-bed pressure swing adsorption (PSA) nitrogen separation technology is superior to other membrane systems, generating more nitrogen with less feed air, providing 98% pure nitrogen.

The South-Tek N2-Blast Corrosion Inhibiting System

How serious of a problem is corrosion in dry fire sprinkler systems?

73% of dry and pre-action fire sprinkler systems inspected had significant corrosion issues after 12.5 years of normal use (VDS Study).

Corrosion leads to property damage, ongoing pipe repair and replacement, decreased c-factor and sprinkler head blockage – potentially rendering the system inoperable in the event of a fire.

Test Results

Black Steel: The calculated service life of black steel pipe increases from 20 years to 63 years.

Galvanized Steel: The calculated service life of galvanized steel pipe increased from 10 to 176 years.

For more information see South-Tek Systems Corrosion Inhibiting Solutions.

What causes pinhole leaks in fire sprinkler systems?

Protecting Wet Fire Sprinkler Systems from Corrosion